1905 movie network feature Recently, the "uncle circle style" has swept across the screen. What impresses people is not only their superb acting skills, but also the unique male charm created by their suits. Different materials, different colors, different styles, and different collar tips, these suit languages not only bring us visual enjoyment, but also convey what information to us? This issue of "Today’s Film Review" invited Jia Xizeng, an associate professor at the Academy of Fine Arts of Tsinghua University, to open the uncles’ wardrobes with us and chat about the sociology in their suits.

What changed was the suit, and it was also an era. The language of the suit was in step with the trend of the times, and the movie Heli showed the clothes between the 1930s and 1940s. This period was the golden age of the suit. During this period, there were many occasions to wear the suit, and the suit even became one of the most common clothes in life.

@Jia Xizeng:In these two films, the matching of suits and the language of costumes are both rigorous and orthodox.

The show is around 2000, when the suit has become fashionable, it not only inherits the tradition, but also adds some contemporary fashion features. By then, the suit in the movie has become a fashion trend and has become a daily trend.

The wardrobe of the movie "Nameless" – showing status and character

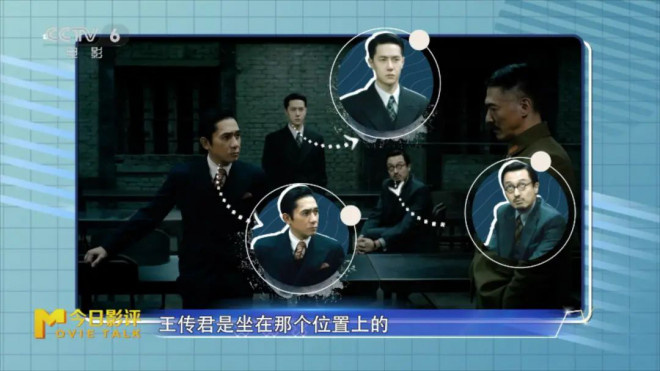

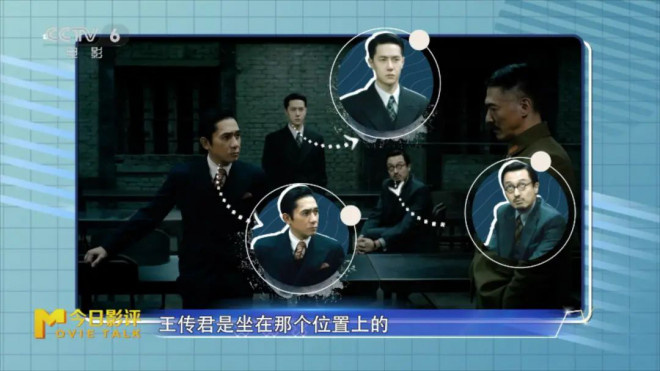

The characters in the movie "Nameless" are basically dressed in dark suits, which convey a sense of unity, depth and restraint, which is in line with the plot and style requirements of spy movies. On a poster, standing in front, sitting behind, the three people have different clothing styles. As an underground worker who penetrated the enemy’s interior, Leung Chaowei needed to be calm and low-key, and he wore a six-button barge suit.

@Jia Xizeng:Because he is the first protagonist, the message conveyed by the costume is also the strongest.

Wang Yibo is also wearing a slender head, wearing a wide-shouldered H-shaped (straight), and even a little T-shaped (silhouette) suit, which conforms to the silhouette characteristics of male heroes. The collar of the suit is stiff, like a blade, which matches Wang Yibo’s handsome and bold image. Minister Tang, who plays the role, is more advanced in his attire. By comparing the suits of these three people, we can find that the higher the status, the higher the barge, and the higher the barge. Minister Tang’s attire shows his high position and weight through the design of the collar pin, which instantly distinguishes him from the characters played by Tony Leung and Wang Yibo.

@Jia Xizeng:This is a complete visual language formed by the logical support of color language, clothing language and character language.

Gao Qiqiang’s Wardrobe – The Transformation of Status and Identity

Gao Qiqiang went from being a fish seller to gradually blackening, and his wardrobe was also gradually changing. In the play, Gao Qiqiang’s life is ups and downs. In each period, he has different clothes, the jacket he wears when selling fish, the gray-green suit when the PHS store opens, and the different styles of suits he wears when dealing with different affairs after being instructed by Chen Shuting.

@Jia Xizeng:In fact, clothing is a process of human interaction, so how to reflect etiquette, respect, and a sense of value, through clothing can achieve the finishing touch.

The difference between a barred collar, a flat barred collar and a green fruit collar

In "Hurricane", Gao Qiqiang’s camouflage-collared suit has a particularly high appearance rate. In terms of clothing etiquette, the camouflage-collared suit is of a higher level and shows a greater aura. The camouflage-collared suit is more in line with his role identity. Compared with the camouflage-collared collar, the camouflage-collared collar is more conventional, more low-key, more restrained, and more daily. When Gao Qiqiang attended a leadership meeting in the city, he wore a camouflage-collared suit with a white shirt and no tie, which cleverly avoided high-profile. The green fruit collar is a collared style. It does not have the opening and closing of the neckline. It belongs to a type of dress. It is common on important occasions and is rare in daily life. Last year’s Golden Rooster Awards ceremony was accompanied

People rely on clothes, "Uncle relies on suits", and in future films, we can also figure out the background of the characters from their suits. Li Dapeng wore an orange suit, which is more fashionable and personalized, and is not suitable for daily occasions. In terms of cultural connotation of hue, orange echoes his image of being bohemian on the surface, full of sense of justice in the heart, and enthusiastic about helping others.

In the trailer, Zhu Yilong is wearing casual clothes, but the poster of Zhu Yilong is wearing a formal two-button suit with a white shirt backing, but not a tie. This suit style conflicts with his casual state. It is speculated that it is the director’s deliberate setting, which is intended to suggest that the character played by Zhu Yilong in the movie has different personalities – fickle and hidden.

|

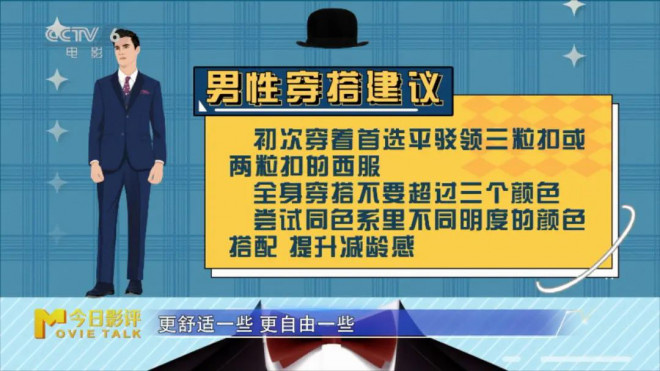

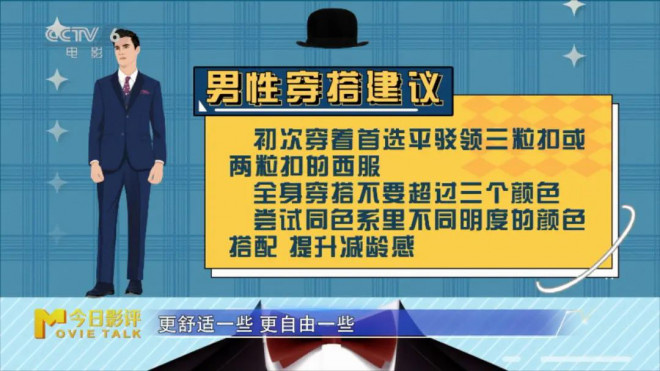

Dressing is a way of life, but also a way to love life. During the program, Jia Xizeng also shared some clothing suggestions with the audience and friends.

From movies to reality, from the highest ceremonial occasions to daily life, suits have brought us different meanings and values. We also hope that suits can be more everyday, making them a must-have wardrobe that accompanies our daily lives.